- Backflow

Backflow or BACKSIPHONAGE of contaminated water through cross connections to the water distribution system must be prevented. Backflow into the distribution system occurs when the consumerís pressure is HIGHER than the pressure in the distribution piping. Typical situations that cause low pressures in distribution systems occur when very high flows are experienced in the distribution system. Fire flows and watermain breaks, for example, produce isolated points of high demand. Because of these high demands, the HYDRAULIC GRADE LINE is lowered BELOW the elevation of the service connection. This causes water to flow from the service connection into the main.

- Backflow Devices

Backflow devices and methods that are used to eliminate the threat of back siphonage include the following: 1) Air Gap Separation; 2) Reduced Pressure Devices; 3) Double Check Valve; and, 4) Vacuum Breakers.

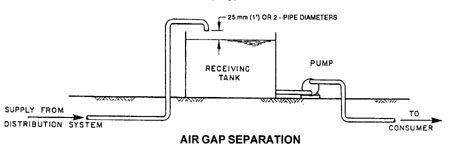

- Air Gap Separation

Air gap separation (as shown in the figure below) is used to sever the direct connection between the main and the service. Water is supplied to a tank and controlled by a level control device. The distance between the supply piping and the highest level of the receiving storage should provide at least a 2.5 cm (1 inch) air gap or twice the diameter of the supply pipe, whichever is larger. All piping and the tank should be above grade and visible for inspection by the municipality unless otherwise approved by regulating agencies.

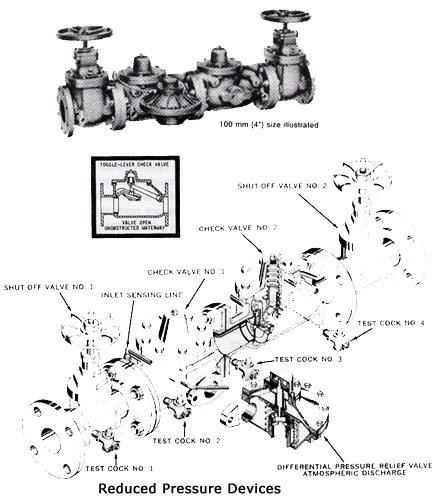

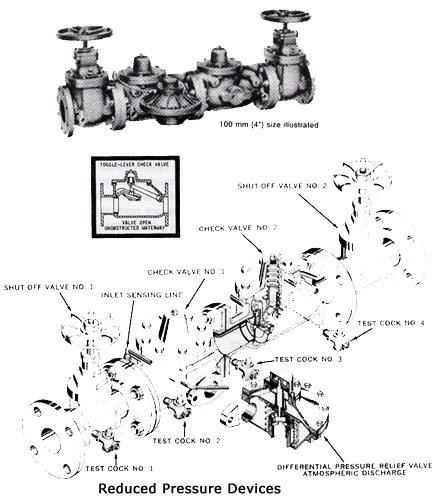

- Reduced Pressure Devices

Reduced pressure devices (see figure below) are used where dangerous materials are present at the user location or where the possibility of backflow is high. The device consists of a double check valve assembly with a relief valve between the check valves. When low pressures develop in the distribution system, both check valves close as the water attempts to flow back towards the distribution piping. If the check valves fail to close properly, the relief valve between the check valves opens and water from the service is discharged from the valve to atmosphere. If backsiphonage occurs with the suppy pressure dropping to two psi or less, the relief valve will remain fully open creating an air gap between the teo check valves.

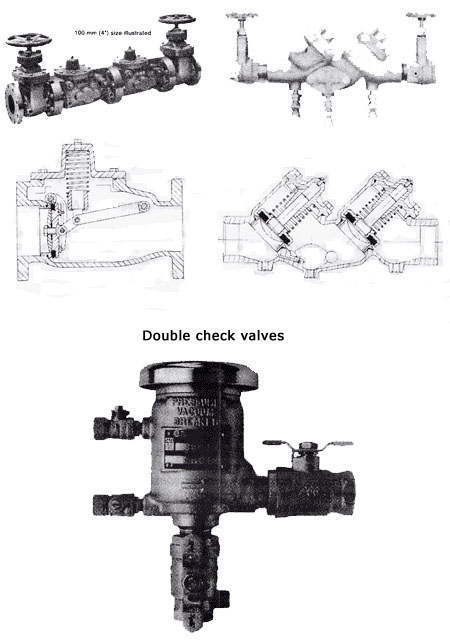

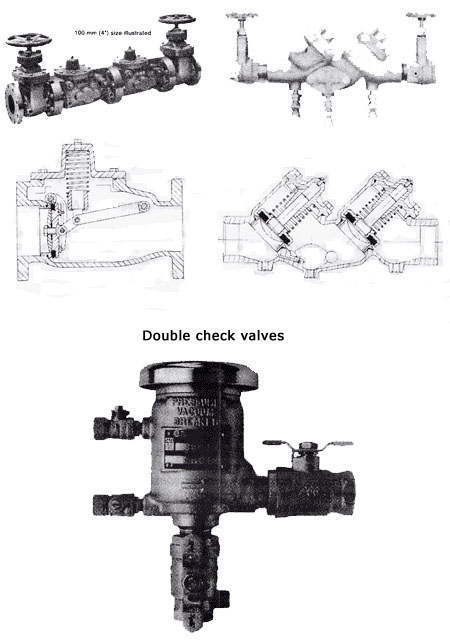

- Double Check Valve

Double check valves (see figure below) consist of two internally loaded, independent check valves located between two shut off valves. Four test cocks are included in the assembly. Under normal pressure, the check valves are held open by system pressure, allowing flow to pass through. When the service side of the assembly is higher than the supply pressure, the two check valves close and prevent water from passing back through the valves. These types of valves should be tested at least once every three months.

- Vacuum Breakers

Vacuum breakers (see figure below) are not used on service connection applications but more often of systems such as irrigation systems. With vacuum breakers, air is supplied into the pipeline when backflow occurs. Vacuum breakers are normally restricted to private systems where these devices are used to protect equipment and piping systems.

- Operation and Maintenance

Operation and maintenance procedures to prevent backflow include:

- System Pressure

A continuous POSITIVE PRESSURE in the distribution system during all flow conditions can prevent backflow. Pressures in the system should be maintained at a minimum of 240 kPa (35 psi) at all points in the distribution system. Supply pumps, reservoirs, and booster pumps should be operated to maintain pressures above 240 kPa (35 psi) but not exceeding 550 to 690 kPa (80 to 100 psi). Excessive pressure can cause extensive damage to other water facilities.

If low pressures are reported by consumers, an investigation should be started immediately. Pressure gauges can be used to measure system pressures in suspected low pressure areas.

- Valves

Faulty pressure control valves or closed valves can create low pressures in the distribution system. With closed valves in the distribution system, fewer pipes are available to carry flows. Because of the increased flows, pipes develop higher pressure losses throughout the distribution system. Areas that are at the furthest extent of the system or that are in elevated areas will experience low pressures. In these areas, backflow can occur if the pressure drops below atmospheric pressure (partial or full vacuum).

- Storage Reservoirs

Storage reservoirs that supply gravity flow into the distribution system should be maintained at full operating level. By maintaining a full suplly level, the reservoir can provide flows into the distribution system and help to equalize system pressures. If the level is low, the distribution of flow through the distribution system may become imbalanced and cause high pressure losses and lower system pressures. The possibility of backflow increases as the system pressure drops.

- Pumps

Pumps suffer from mechanical wear and age and must be maintained for peak performance. If the pump fails, system pressures will drop accordingly. The resulting drop is system pressure can lead to negative pressures developing in the elevated areas of the distribution system as lower areas continue to use water. To prevent lowering system pressure caused by pump or electrical power disruptions, stand-by pumps, engine driven pumps, and generators are needed.

- Prevention

Municipalities can control the possibility of backflow contamination in a number of ways:

- Reviewing Service Applications

Water service applications and connections should be rejected if the possibility of backflow through unprotected connections can occur. Non-potable water consumers connected to the system should be instructed to install appropriate backflow prevention devices before service is granted. Supply and installation costs of devices may have to be borne by the municipality.

- Contacting Regulating Agencies

Plumbing inspection branches, local health agencies, and provincial agencies should be contacted as needed to inspect, advise, and enforce their respective regulations.

- Maintenance and Testing

Backflow devices owned by either the municipality or consumers should be maintained and tested regularly to ensure their operation. Each backflow device connected to the system should be recorded. Dates of maintenance and testing information must also be recorded.

- Operation and Maintenance

Proper operation and maintenance of municipal facilities will prevent the occurrence of low pressures in the distribution systems.

|