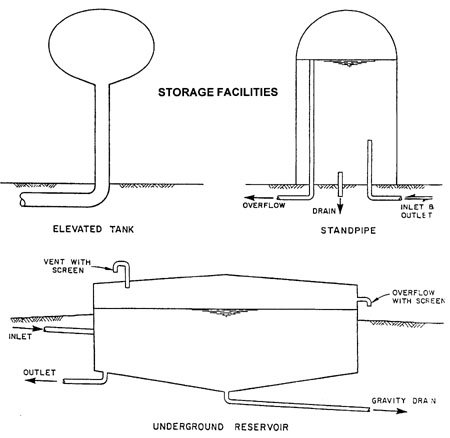

Common types of storage facilities include underground reservoirs, elevated tanks, and standpipes. See illustration below.

In smaller systems, hydropneumatic tanks are used. A description of each follows.

- Underground Reservoirs

Underground reservoirs are usually constructed of concrete. They are built into the ground and buried to provide protection against freezing. If incorporated as part of a water treatment plant, the reservoir also provides process water for the plant operation and is called a CLEAR WELL.

Underground reservoirs vary in depth ranging from a minimum of 3 m (10 feet) to over 7.7. m (25 feet). The deeper depths predominate in large storage facilities normally found in cities.

- Elevated Tanks

Elevated tanks provide a smaller storage volume than other comparable storage facilities and are chiefly used to maintain system pressure. The height or relative elevation of the elevated tank is determined by the desired system pressure.

Water is pumped into the elevated reservoir during times of low flow and flows out during periods of high demand. Flow in and out of the tank is controlled by level control switches and flow control valves. When the level in the tank reaches the full level, flow into the reservoir is stopped.

- Standpipes

Standpipes are normally constructed using steel or concrete. They are circular with their heights exceeding their diameters. The standpipe is built to a pre-determined height equal to the pressure desired at that location. Available pressures vary with the depth of water in the standpipe. Lower levels in the standpipe, however, provide only marginal pressure to the distributive system.

- Hydropneumatic Tanks

Hydropneumatic tanks are small volume pressurized tanks that supply water to the system under pressure. Typical applications are found in smaller distribution systems. Because the volume contained in the tank is relatively small, hydropneumatic tanks do not significantly reduce the required capacity of other water facilities.